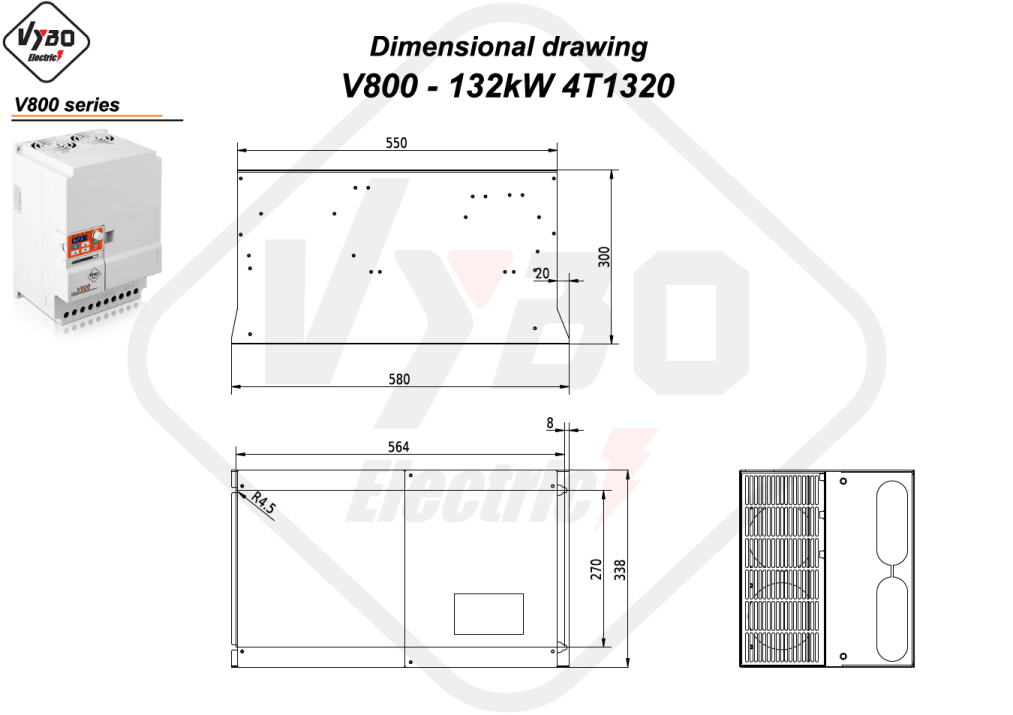

3D visualization

VYBO Electric

| Model | V800-4T1320 |

| Power | 132 kW |

| Nominal output current | 253 A |

| Input voltage 50/60Hz | 3 Phases 400V |

| Output voltage 50/60Hz | 3 Phases 400V |

| Power cable cross section | 120 mm² |

| Brake unit | No |

| EMC filter | Yes (C2) |

If you have any questions, please do not hesitate to contact us:

100% safe payment

3D visualization

VYBO Electric

Frequency converter 132kW 400V V800-4T1320 is in stock. Introducing VYBO Electric’s V800-4T1320 Frequency converter (VFD), designed to provide exceptional control and efficiency for a variety of industrial applications. We are proud to offer this high quality VFD along with a fast delivery service to cities across the United Kingdom.

The V800 series frequency converters feature advanced vector control technology that ensures precise and professional drive control. Manufactured to the highest standards, these VFDs are equipped with robust software and a variety of features to ensure they function smoothly in even the most demanding heavy industry conditions. Thanks to its plug-and-play design, the V800-4T1320 is fully pre-programmed and ready to use immediately after connecting to the mains.

Whether it’s controlling conveyor belts in Leeds, driving assembly lines in Birmingham or optimizing industrial processes in Edinburgh, the 132kW V800 frequency converter proves its versatility and reliability. Its exceptional overload capability makes it suitable for the most demanding applications, providing reliable and efficient performance even under heavy loads. One of the main advantages of using a variable frequency drive such as the V800-4T1320 is its ability to control the speed of electric motors, resulting in significant energy savings and process optimization. Reducing engine speed effectively reduces mechanical wear and extends the life of your equipment. Experience the benefits of energy efficiency and longer machine life by choosing the V800 series vector frequency inverters.

With features such as open-loop SFVC vector control, a wide output frequency range of 0.01 to 3200 Hz and an integrated braking unit, the 132kW V800 VFD offers unparalleled flexibility and functionality. Its built-in EMC filter ensures reliable performance and compliance with electromagnetic compatibility standards. In addition, it is equipped with standard features such as automatic voltage regulation (AVR), programmable logic controller (PLC), JOG function, timers and comprehensive protection functions.

For additional convenience, the Frequency converter 132kW V800 has an EMS immediate stop function and the option of connecting PTC protection or a thermal contact for motor protection. The removable panel allows external installation up to 50 meters via a cable, providing flexibility in system integration. Make your operations more efficient, reliable and cost-effective with the V800 frequency converter from VYBO Electric. Benefit from our reliable delivery service to cities across the United Kingdom and experience the superior performance of our VFDs. Contact us today and move your business forward.

In addition to its exceptional performance and advanced features, the VFD V800-4T1320 features the manufacturing expertise of VYBO Electric. Our quality commitment ensures that you receive a durable and reliable product that meets your specific industrial requirements. With our efficient delivery service, we want to provide timely access to the 132kW V800 VFD so that companies in Glasgow, London, Manchester and other cities in the United Kingdom can improve their operations and achieve maximum productivity. Experience the power of the V800 series and revolutionize your industrial processes today.

| V800 inverter model type | Nominal output power (kW) | Nominal input current (A) | Rated output current (A) | Recommended motor power (kW) |

| V800-4T1320 | 132 | 260 | 253 | 132 |

| Input voltage (V) 50/60 Hz | Motor power (kW) | Recommended cable cross section (mm²) | Recommended circuit breaker (A) | |

| 3 Phases 3×400 V | 132 | 120 | 315 | |

Table of suitable braking resistors

| Frequency converter type | Brake resistor | Brake unit | Recommended motor power (kW) | |

| Resistance power (kW) | Resistance value (Ω) (≥) | |||

| V800-4T1320 | 5,5×2 | 9,4×2 | External | 132 |

General technical parameters for all V800 types

| Element | VECTOR V800 | |

|---|---|---|

| Control mode | V/F scalar control SFVC idle vector |

|

| Maximum frequency | SFVC vector control: 0 – 320 Hz V/F scalar control: 0 – 3200 Hz |

|

| Carrier frequency | 1-16 kHz The carrier frequency is automatically set based on the load characteristics. |

|

| Input frequency resolution | Digital setting 0.01 Hz Analogue setting: maximum frequency x 0.025% |

|

| Initial torque | G-Type: 0.5 Hz/150% (SVFC) P-Type: 0.5Hz/100% |

|

| Speed range | 1:100 (SFVC) | |

| Speed stability | ± 0.5% (SFVC) | |

| Precise torque control | ± 5% (SFVC) | |

| Overload size | G type: 60s for 150% of rated current, 3s for 180% of rated current P-Type: 60s for 120% of rated current, 3s for 150% of rated current. |

|

| Torque increase | Fixed torque gain User increase 0.1% to 30.0% |

|

| EMC filter | Integrated with the “C1” designation of the C1 class. No Class C2 designation. |

|

| V/F curve | Straight lines V/F curve Multipoint V/F curve N-voltage V/F curve (multiple of 1.2-voltage, 1.4-voltage, 1.6-voltage, 1.8-voltage, modified) |

|

| V/F separation | Two types: complete separation; half separation | |

| Ramp modes | Linear curve S-curve ramp Four groups of acceleration/deceleration times with a range of 0.0-6500.0 s |

|

| DC braking | Brake frequency: 0.3 Hz to maximum frequency Braking time: 0.0-100.0s Current value when braking: 0.0%-100.0% |

|

| Control in JOG mode (step operation) | JOG frequency range: 0.00-50.00 Hz JOG acceleration/deceleration time: 0.0-6500.0 s |

|

| Implement. more preset speeds | Up to 16 speeds implemented via a simple PLC function or a combination of X end states. | |

| Built-in PID controller | Enables a process-controlled control system. | |

| AVR automatic voltage regulation | It can automatically maintain a constant output voltage when the supply voltage changes. | |

| Overvoltage and overcurrent regulator | Current and voltage are automatically limited during operation to prevent frequent shutdowns due to over-voltage and over-current. | |

| Torque limitation and steering | It can automatically limit the torque and prevent the overcurrent from changing frequently during operation. | |

| EMS STOP safety function | The “Emergency STOP” system: In emergencies, it stops the inverter immediately after EMS STOP has been activated. | |

| Fast current limitation | Prevents common overcurrent faults in AC motors | |

| High performance | AC motor control is realized by powerful current vector control technology. | |

| Time management | Time range: 0.0-6500.0 minutes | |

| Communication protocol | RS485 MODBUS RTU | |

| Execute command channel | Depending on the panel, control terminals and serial communication port, can be switched in many ways | |

| Frequency source | 10 kinds of frequencies, given by digital analog voltage, analog current, pulse, serial port, can be switched in many ways | |

| Auxiliary frequency source | 10 kinds of frequencies, micro-adjustment can be easily realized, frequency synthesizer | |

| Input and output | Input terminal blocks | 6 digital inputs, 2 analog inputs, one of which supports 0-10V input and the other supports 0-10V or 4-20mA input. |

| Output terminal blocks | 1 digital output 1 relay output, 1 analog output terminal, with output 0-20mA / 0-10 V |

|

| LED display | Show parameters | |

| Key lock and function selection | It can partially or completely block buttons and define the functionality of some buttons to prevent malfunctions. | |

| Protection mode | Motor short circuit detection at power-on, phase loss protection, over-current protection, over-voltage protection, under-voltage protection, over-temperature protection and overload protection. | |

| EMC (compactability) | IEC 61000-4-6; IEC 61000-4-4; IEC 61000-4-11; IEC 61000-4-5 | |

| Standards | EN/IEC 61800-3: 2017; C1, which is suitable for the 1st environment; EN/IEC 61800-3: 2017; C2, which is suitable for the 1st environment; |

|

| Environmental installation | Avoid indoor exposure to direct sunlight, salt, dust, corrosive or flammable gases, smoke and steam. Resistance to chemical pollution, class 3C3 EN/IEC 60721-3-3. Resistance to dust pollution 3S3EN/IEC 60721-3-3. |

|

| Alt. Height. | Below 1000 meters above sea level. (reduce the load level when used above 1000 meters above sea level) | |

| Ambient temperature | -10°C ~ 40°C (Reduce the power level when the ambient temperature is between 40°C and 50°C) | |

| Humidity | Less than 95% relative humidity, non-condensing IEC 60068-2-3 |

|

| Vibrations | Less than 5.9 m/s2 (0.6 g) IEC 60068-2-6 | |

| Storage temperature | -20°C to +60°C | |

| 1PH / 3PH AC 230V ±15% | ||||

| Inverter model type V800 | Rated power (kW) | Maximum input current (A) | Rated output current (A) | Recommended motor power (kW) |

| V800-2S0004 | 0,4 | 5.4 | 2.4 | 0,4 |

| V800-2S0007 | 0,75 | 7.2 | 4.5 | 0,75 |

| V800-2S0015 | 1,5 | 10 | 7 | 1,5 |

| V800-2S0022 | 2,2 | 16 | 10 | 2,2 |

| V800-2S0030 | 3 | 23 | 16 | 3 |

| 3PH / 3PH AC 400 V ±15 % | ||||

| V800-4T0007 | 0,75 | 3.8 | 2,5 | 0,75 |

| V800-4T0015 | 1,5 | 5 | 3.7 | 1,5 |

| V800-4T0022 | 2,2 | 5.8 | 5 | 2,2 |

| V800-4T0040 | 4 | 10 | 9 | 4 |

| V800-4T0055 | 5.5 | 15 | 13 | 5.5 |

| V800-4T0075 | 7,5 | 19 | 17,5 | 7,5 |

| V800-4T0110 | 11 | 26 | 25 | 11 |

| V800-4T0150 | 15 | 35 | 32 | 15 |

| V800-4T0220 | 22 | 46 | 45 | 22 |

| V800-4T0300 | 30 | 62 | 60 | 30 |

| V800-4T0370 | 37 | 76 | 75 | 37 |

| V800-4T0370 | 37 | 76 | 75 | 37 |

| V800-4T0450 | 45 | 92 | 90 | 45 |

| V800-4T0550 | 55 | 112 | 110 | 55 |

| V800-4T0750 | 75 | 155 | 150 | 55 |

| V800-4T0900 | 90 | 180 | 176 | 90 |

| V800-4T1100 | 110 | 215 | 210 | 110 |

| V800-4T1320 | 132 | 260 | 253 | 132 |

| V800-4T1600 | 160 | 310 | 300 | 160 |

| V800-4T1850 | 185 | 350 | 340 | 185 |

| V800-4T2000 | 200 | 390 | 380 | 200 |

| Input voltage (V) 50/60Hz | Motor power (kW) | Recommended cable cross section (mm²) | Recommended breaker (A) | Recommended input contactor (A) | |

| V800-2S0004 | 1 Phase 1×230 V | 0,4 | 1,5 | 10 | 10 |

| V800-2S0007 | 0,75 | 1,5 | 16 | 16 | |

| V800-2S0015 | 1,5 | 2,5 | 25 | 25 | |

| V800-2S0022 | 2,2 | 4 | 32 | 32 | |

| V800-2S0030 | 3 | 4 | 40 | 40 | |

| V800-4T0004 | 3 Phases 3×400 V | 0,4 | 1,5 | 6 | 6 |

| V800 -4T0007 | 0,75 | 1,5 | 6 | 6 | |

| V800-4T0015 | 1,5 | 1,5 | 6 | 6 | |

| V800-4T0022 | 2,2 | 1,5 | 10 | 10 | |

| V800-4T0040 | 4 | 2,5 | 16 | 16 | |

| V800-4T0055 | 5.5 | 2,5 | 20 | 20 | |

| V800-4T0075 | 7,5 | 4 | 32 | 32 | |

| V800-4T0110 | 11 | 4 | 32 | 32 | |

| V800-4T0150 | 15 | 6 | 40 | 40 | |

| V800-4T0185 | 18,5 | 10 | 50 | 50 | |

| V800-4T0220 | 22 | 10 | 50 | 50 | |

| V800-4T0300 | 30 | 16 | 63 | 63 | |

| V800-4T0370 | 37 | 25 | 100 | 100 | |

| V800-4T0450 | 45 | 25 | 100 | 100 | |

| V800-4T0550 | 55 | 35 | 125 | 125 | |

| V800-4T0750 | 75 | 50 | 160 | 160 | |

| V800-4T0900 | 90 | 70 | 225 | 225 | |

| V800-4T1100 | 110 | 95 | 250 | 250 | |

| V800-4T1320 | 132 | 120 | 315 | 315 | |

| V800-4T1600 | 160 | 120 | 350 | 350 | |

| V800-4T1850 | 185 | 150 | 400 | 400 | |

| V800-4T2000 | 200 | 185 | 500 | 500 |

Table of suitable braking resistors V800

| Frequency converter type | Brake resistor | Brake unit | Recommended engine power (kW) | |

| Resistance power (kW) | Resistance value (Ω) (≥) | |||

| V800-2S0004 | 0,08 | 200 | Integrated | 0,4 |

| V800-2S0007 | 0,08 | 150 | Integrated | 0,75 |

| V800-2S0015 | 0,10 | 70 | Integrated | 1,5 |

| V800-2S0022 | 0,10 | 70 | Integrated | 2.2 |

| V800-2S0030 | 0,25 | 65 | Integrated | 3 |

| V800-4T0004 | 0,15 | 300 | Integrated | 0,4 |

| V800-4T0007 | 0,15 | 300 | Integrated | 0,75 |

| V800-4T0015 | 0,15 | 220 | Integrated | 1,5 |

| V800-4T0022 | 0,25 | 200 | Integrated | 2.2 |

| V800-4T0040 | 0,3 | 130 | Integrated | 4 |

| V800-4T0055 | 0,4 | 90 | Integrated | 5.5 |

| V800-4T0075 | 0,5 | 65 | Integrated | 7.5 |

| V800-4T0110 | 0,5 | 65 | Integrated | 11 |

| V800-4T0150 | 0,80 | 43 | Integrated | 15 |

| V800-4T0185 | 1 | 32 | Integrated | 18,5 |

| V800-4T0220 | 1.3 | 25 | Integrated | 22 |

| V800-4T0300 | 1,5 | 22 | Integrated | 30 |

| V800-4T0370 | 2,5 | 16 | Integrated | 37 |

| V800-4T0450 | 3.7 | 12.6 | Integrated | 45 |

| V800-4T0550 | 4.5 | 9.4 | External BU | 55 |

| V800-4T0750 | 5.5 | 9.4 | External BU | 75 |

| V800-4T0900 | 7,5 | 6.3 | External BU | 90 |

| V800-4T1100 | 4,5 x 2 | 9,4 x 2 | External BU | 110 |

| V800-4T1320 | 5,5 x 2 | 9,4 x 2 | External BU | 132 |

| V800-4T1600 | 6,5 x 2 | 6,3 x 2 | External BU | 160 |

| V800-4T1850 | 16 | 2,5 | External BU | 185 |

| V800-4T2000 | 6,5 x 3 | 6,3 x 3 | External BU | 200 |

| Rated power at normal load (normal operation) | 132 kW |

| High performance performance | 110 kW |

| Nominal output current | 253 A |

| Supply voltage | 3 x 400V |

| Output voltage | 0 – 400 V |

| Output frequency | 0 – 3200 Hz |

| Overload capability in ND mode – Normal Duty | 120% / 60s |

| Overload in HD mode – Heavy Duty | 150% / 60s |

| Control mode V/F scalar control | ✓ |

| SFVC vector open loop control mode | ✓ |

| CLVC vector control mode | X |

| Analog inputs | 2 |

| Digital inputs | 6 |

| Analog outputs | 1 |

| Relay outputs | 1 |

| Open Collector Outputs | 1 |

| Integrated brake transistor | X |

| EMC filter | ✓ |

| +10V output | ✓ |

| +24 V output | X |

| Input for PTC | ✓ |

| Safe Torque Off (STO) | X |

| Emergency stop (EMS) | ✓ |

| Integrated Ethernet | X |

| Integrated MODBUS RTU | ✓ |

| PROFIBUS | X |

| PG card for encoder | X |

| PID | ✓ |

| Intelligent PLC function | ✓ |

| External panel connection (typically up to 30 m) | ✓ |

| Protection class IP 20 | ✓ |

| Protection class IP 65 | X |

| Change direction of rotation via external input | ✓ |

| Change direction of rotation in the control panel | X |